In the demanding world of professional landscaping, every dollar spent on gasoline is a direct impact on your profits. The choice of engine—a lightweight 2-stroke or a heavy-duty 4-stroke—for your trimmers, blowers, and mowers is critical to both performance and long-term operating costs.

While 2-stroke engines are known for their power and minimal weight, 4-stroke engines are the clear winner when it comes to superior fuel efficiency and cleaner operation.

Here’s a breakdown of the efficiency showdown to help you choose the most economical engine for your fleet.

The Fundamental Flaw of the 2-Stroke Design

The core reason 2-stroke engines are less fuel-efficient lies in their simplified operation cycle. They complete a power cycle in just two piston strokes (one crankshaft revolution), which unfortunately leads to fuel being wasted.

- Scavenging Loss: To keep the design simple and lightweight, the 2-stroke engine uses the movement of the piston to open and close intake and exhaust ports. During the scavenging phase (when the spent exhaust gases are being pushed out), the fresh, new fuel-air-oil mixture enters the cylinder at the same time.

- Wasted Fuel: This overlap means that a portion of the unburned fresh fuel mixture is pushed straight out of the exhaust port along with the exhaust. This lost fuel contributes to high emissions, a distinct smoky smell, and significantly lower fuel economy.

- Constant Oil Burn: Because the lubricating oil is premixed with the gasoline, it is consumed in the combustion process, which is an inefficient and polluting method of lubrication.

4-Stroke: The Efficiency Champion

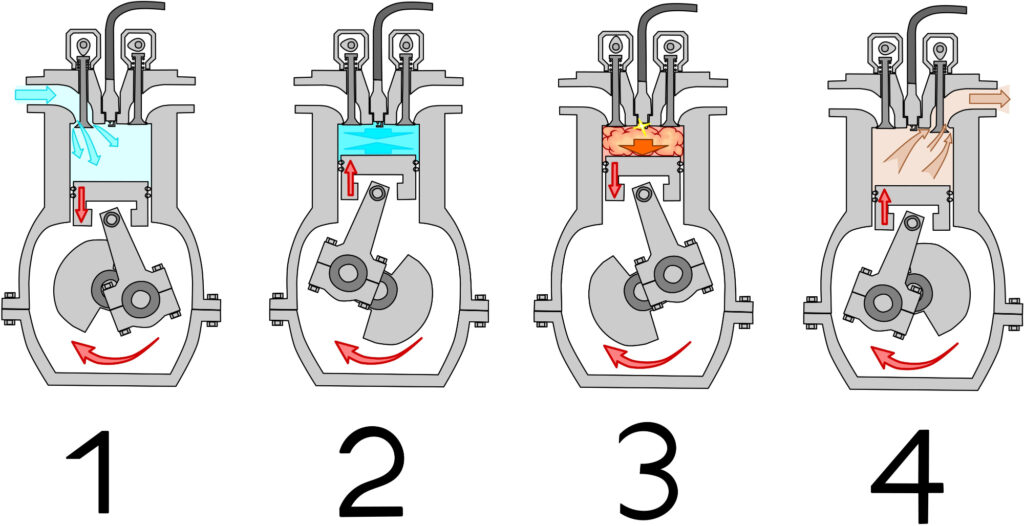

The 4-stroke engine (Intake, Compression, Power, Exhaust) requires two full crankshaft revolutions to complete one power cycle. This complexity is what makes it superior in efficiency.

- Precise Valve Control: 4-stroke engines use dedicated intake and exhaust valves that open and close at precise moments. This separation ensures that the fuel mixture is fully contained and compressed before ignition, and the exhaust only leaves after the power stroke is complete.

- Zero Fuel Loss: With no overlap between fresh fuel intake and exhaust expulsion, virtually none of the unburnt gasoline is wasted. This results in a cleaner, more complete burn and greater energy extraction from every drop of fuel.

- Dedicated Lubrication: The engine runs on pure gasoline because the oil is held in a separate crankcase reservoir (like a car engine). This separate, dedicated lubrication system prevents oil from being burned with the fuel, further maximizing combustion efficiency.

Real-World Impact on Your Landscaping Business

The efficiency benefits of 4-stroke engines have a direct and cumulative impact on professional operations:

| Feature | 2-Stroke Engine | 4-Stroke Engine | Direct Business Impact |

| Fuel Consumption | High (Less efficient) | Low (Up to 50% less) | Significant cost savings over a season. |

| Fuel Prep | Requires precise fuel/oil mixing | Uses straight unleaded gasoline | Saves labor time and eliminates risk of engine damage from improper mix. |

| Weight & Torque | High power-to-weight ratio (lighter) | Higher weight, better low-end torque | Better for sustained, heavy-duty tasks like mowing and heavy brush cutting. |

| Emissions | High (due to burning oil) | Low | Compliance with strict local emission and noise ordinances. |

| Upfront Cost | Generally lower | Generally higher | Higher initial investment but quickly offset by long-term fuel savings. |

The Bottom Line: While the 2-stroke remains the choice for applications where the absolute lightest weight and highest power-to-weight ratio are critical (like some chainsaws or small handheld blowers), the 4-stroke engine is the superior long-term investment for the fuel-conscious landscaper. Its low consumption and durable design translate directly into fewer trips to the pump and a longer lifespan for your expensive equipment.

❓ Would you like to see a comparison of the typical maintenance costs between 2-stroke and 4-stroke landscaping engines?